Fanuc

RoboDrill DIB Medium Bed Advanced Series

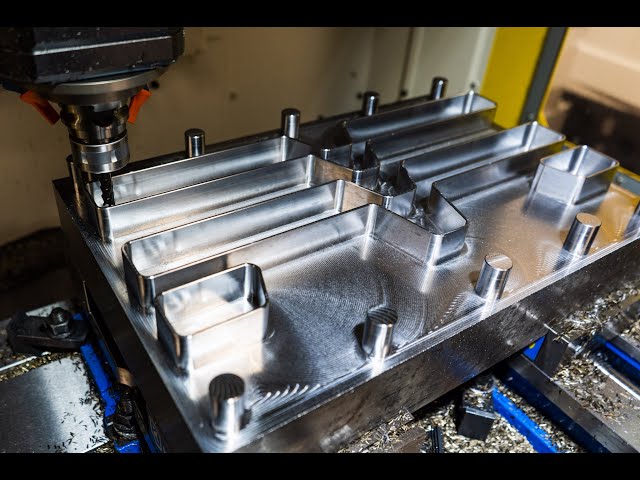

The FANUC RoboDrill DIB Medium Bed is a high-performance machining center, known worldwide as the most reliable machine manufactured today.

RoboDrills make quick work out of any milling, drilling or tapping jobs. Reliability has also been addressed in all areas of the machine design. Coupled with the latest FANUC 31i-B5 PLUS control, the RoboDrill is the preferred machine in any manufacturing facility, large or small.

All RoboDrills are part of our RTS program, which gives you the choice to receive your RoboDrill when it fits your schedule.

Whether in 5 days or any time after, your RoboDrill will be ready when you are. Guaranteed.

Product Details

Features & Benefits

- Compact Design

- Big Plus Spindle

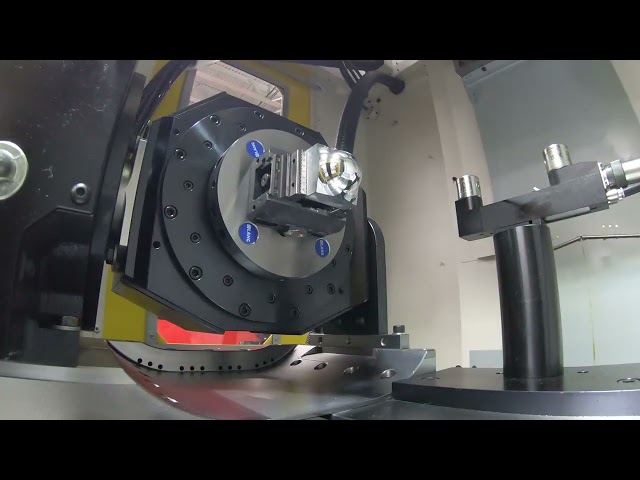

- Up to 5 Axis Simultaneous Machining

- FANUC 31i-B5 Nano CNC System

- Ultra Precise 32,000,000 Pulse/Rev Encoders

- Ai Contour Control I

- Thermal Growth Compensation

- 1.3 sec Chip to Chip

- 1.5G Accel/Decel

- Helical Interpolation Program Storage

- Rigid Tapping 5,000/8,000 RPM

- Thread Milling

- High Speed Reverse Tapping

- “Quick” Tap Recovery System

- Simultaneous ATC / Table Positioning

- Easy to Automate with Methods

- Built 100% in Japan

Technical Data

Travel

- X-Axis Travel

- 19.7 (500) in (mm)

- Y-Axis Travel

- 15.7 (400) in (mm)

- Z-Axis Travel

- 15.7 (400) in (mm)

- Spindle to Table

- 3.1-18.9 (78.7-480) in (mm)

Table Size

- Table Size

- 25.6x15.7 (650x399) in (mm)

- Table Capacity

- 881 (400) lbs (kg)

Weight

- Machine Weight

- 4850 (2200) lbs (kg)

Turret Style ATC Specifications

- Tool to Tool Change Time

- 0.7 sec

- Chip to Chip Change Time

- 1.3 sec

- Max Tool Length

- 9.8 (249) in (mm)

- Max Tool Diameter

- 3.14 (80) in (mm)

Spindles

- Spindle Taper

- BBT-30 Big Plus

- Spindle Speed

- 10000/24000 rpm

- 10000rpm

- 18.7* / 7.5** HP

- 240000rpm

- 34.8* / 7.3** HP

Feedrate

- X-Axis Rapid Traverse

- 2125 (54) in/min (m/min)

- Y-Axis Rapid Traverse

- 2125 (54) in/min (m/min)

- Z-Axis Rapid Traverse

- 2125 (54) in/min (m/min)

ATC

- ATC Type

- Turret Type

- ATC Turret Capacity

- 21 tools

- Tool to Tool Change Time

- 0.07 / 2 kg 0.09 / 3 kg 1.1 / 4 kg

- Chip to Chip Change Time with Table Motion

- 0.07 / 0.07 sec 0.09 / 0.09 sec 1.1 / 1.1 sec

- Control

- Fanuc 31i-B5

- Maximum Programming Memory

- Up to 2gb optional

- Total Simultaneous Axis

- 3 Standard (4/5 Optional)