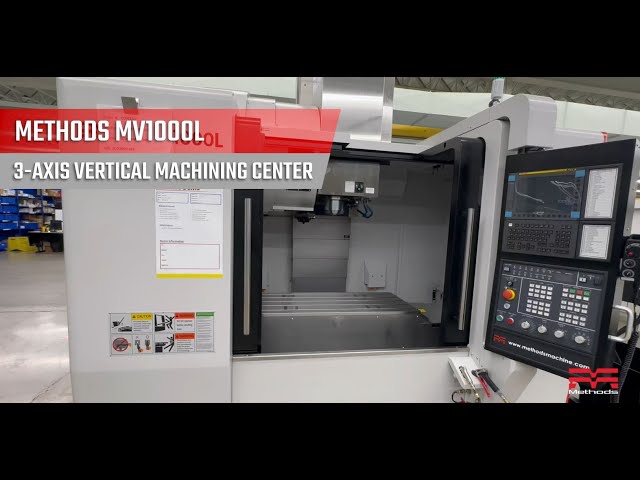

Methods

MV 1000L

The MV-L series of machines combines high-end features such as 19 hand-scraped surfaces, alpha-series FANUC motors, a BIG-PLUS and a dual-contact spindle, and a complete chip management system that includes dual augers, chip conveyor, coolant flush and wash, put the MV-1000L well ahead of the basic industry standards.

“We created the MV 1000L with every shop owner in mind. No matter what type of job you throw at it, this machine will deliver. This is the cornerstone of a machine shop, a Swiss army knife crafted with high-quality components and design features.” – Darren Wall, Methods Product Manager

This RTS machine will be ready to ship to you within 5 days. Guaranteed.

Or call 1-877-668-4262

Product Details

Features & Benefits

- FANUC 0i-MF Plus Control

- Linear rail-type guideways in the X/Y/Z-axes

- Grease lubrication spindle

- Thermal compensation

- 1.8 second tool-to-tool change time

- Complete Chip Management System

- 19 hand-scraped surfaces

Technical Data

Travel

- X Axis

- 39.4 (1000) in (mm)

- Y Axis

- 20.47 (520) in (mm)

- Z Axis

- 20.7 (525) in (mm)

Table

- Table Dimensions

- 45.3x20.5 (1150x520) in (mm)

- Maximum Load

- 882 (400) lbs (kg)

Spindle

- Spindle Speed

- 12,000 RPM

- Spindle Taper

- 40 Taper

- Spindle Power

- 20 HP

Feed Rate

- X/Y/Z Rapid Travel

- 2362/2362/1181 (60/60/30) in/min (m/min)

ATC

- Number of Tools

- 30

- Maximum Tool Weight

- 15.4 (7) lbs (kg)

- Maximum Tool Length

- 11.8 (300) in (mm)

General

- Floor Space

- 107.3 x 96.5 x 118.1 (2725 x 2450 x 3000) in (mm)

- Machine Weight

- 15,432 (7000) lbs (kg)