51

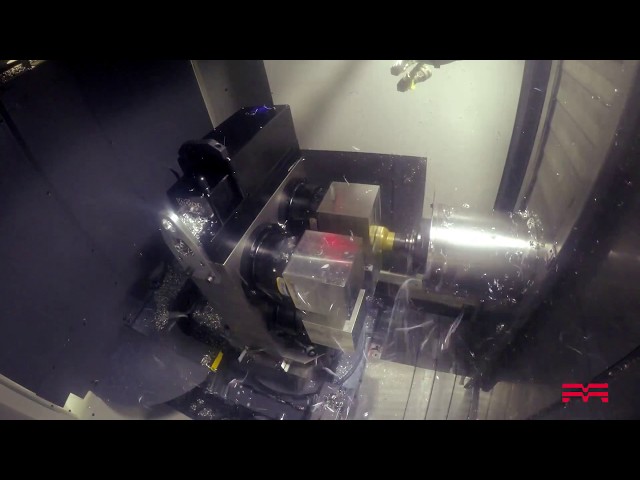

Kiwa

KH-4500kai

KIWA eliminated all possible wasted space on the KH-4500kai Horizontal Machining Center. As a result, the KH-4500kai incorporates one of the largest work envelopes in its class.

KIWA maintains speed and agility, with more than 1G acceleration/deceleration on all axes. The rigidity is enhanced with “stepped” base and column casting design.

Keeping the traditions of KIWA design, the KH-4500kai is fully expandable, both for the APC and ATC portions of the machine. These features are field-installable.

Product Details

Features & Benefits

- (4) Simultaneously Controlled Axes

- Provision for Coolant through Spindle

- Spindle Oil Cooler

- Ballscrew Cooling

- Y-axis Cooling System

- Box Type Bed

- Stepped Layout of X-axis Guide Ways

- Roller Type Guide Way

- Pallet and Chip Wash

- Chip Conveyor – LNS-Turbo MH500

- Spiral Augers

- Tool Life Management

- AICC1

- 1280 meter / 512 kB Memory

- Helical Interpolation

- Macro Programming

Technical Data

Travel

- X-Axis Travel

- 27.6 in (700mm)

- Y-Axis Travel

- 29.1 in (740mm)

- Z-Axis Travel

- 26.8 in (680mm)

- 4th Axis Travel (Rotary Table)

- 0 to 360 degrees

Pallet

- Pallet Surface to Spindle Center

- 2.0-26.0 (50-660) in (mm)

- Pallet Center to Spindle Nose

- 3.9-30.7 (100-780) in (mm)

- Pallet Size

- 15.7x15.7 (400x400) in (mm)

- Pallet Load Capacity

- 1100 (500) lbs (kg)

- Max. Workpiece Size

- ø 29.5 (750) for 2/6APC / ø 25.6 (650) for 8APC in (mm)

- Pallet change Time

- 7.6 sec

Feed Rate

- X-Axis Rapid Traverse

- 3149 (80) in/min (m/min)

- Y-Axis Rapid Traverse

- 3149 (80) in/min (m/min)

- Z-Axis Rapid Traverse

- 3149 (80) in/min (m/min)

- 4Th Axis

- 66 rpm

- Cutting Feed (X/Y/Z)

- 1181 (30) in/min (m/min)

Spindle

- Spindle Power

- 50 (37.5) HP

- Spindle Speed

- 15000 (12000 or a 20000 built-in)

- Spindle Taper

- Cat 40

Tools

- Standard Number of Tools

- 60 (40/80/120/240) std (opt)

- Maximum Tool Weight

- 17.6 (8) lbs (kg)

- Maximum Tool Length

- 15.7 (400) in (mm)

- Maximum Tool Diameter

- ø 2.8/5.5 for 40/60ATC 3.7/7.2inch for 80/120/220ATC (adjacent pots full/empty) in (mm)

- Tool Changing Time- Tool to Tool

- 0.9 (1.7: heavy tool programmable) / 2.8 (3.6: heavy tool programmable) sec

General

- Coolant Tank Capacity

- 145.3 (550) gal (L)

- Machine Weight

- 2APC+60ATC: 20240 (9200) / 2APC+120ATC: 21890 (9950) lbs (kg)

- Machine Control

- FANUC 31iB