51

Methods

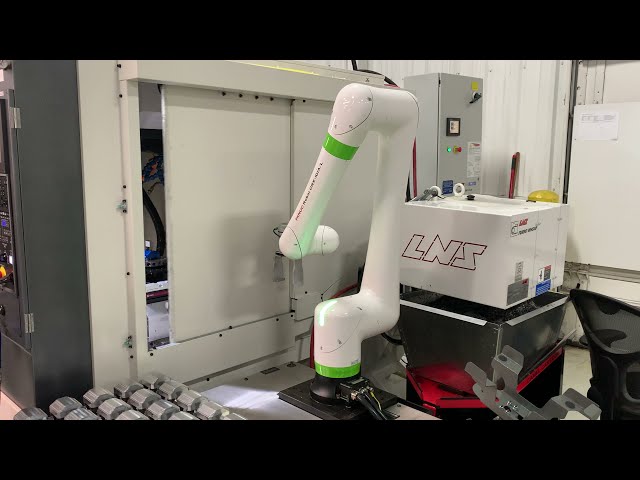

Job Shop Cell Collaborative

The Job Shop Cell Collaborative is an innovative collaborative robotic automation solution designed by Methods to allow easy loading and unloading of parts into your machine tools.

This system will enable machine shops to start introducing automated CNC machining solutions without making a large investment or purchasing new machine tools for the shop.

Request Information

Or call 1-877-668-4262

Product Details

Features & Benefits

Methods Job Shop Cell Collaborative Includes

- Aluminum extrusion framed cart with roller feet for ease of transportation and leveling feet for easy installation

- Infeed/Outfeed pallet storage system in the front of the cart allows for a completely configurable part setup

- Tool storage area within the cart enclosure so no extra work benches are needed

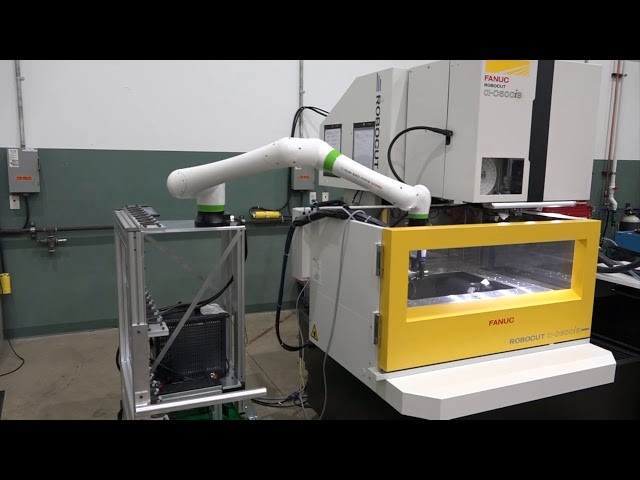

Job Shop cell Collaborative Robot

The FANUC CRX 10iA/L 6-axis articulating arm industrial-grade Cobot with R-30iB Mini Plus Controller includes:

- Ethernet/IP, DCS Position & Speed Check, Karel, and Math Function software options

- Single gripper end of arm tool with either a 2-Jaw or 3-Jaw OnRobot gripper setup

- Methods User Interface: Standard machine load/unload programming to pair with the FANUC RoboDrill utilizing FANUC FOCAS based protocol, making the easy-to-use collaborative robot even easier!

Technical Data

Pallet

- Max Pallet Size (Diameter x Height)

- 19.25” X 29.25”

Work Piece

- Max Weight of Part

- 15 lbs (7kg)

Robot

- FANUC

- CRX-10iA/L

- Robot Reach

- 55” (1418mm)

General

- Floor Space (L x W)

- 47” X 30”

- Unit Weight

- 250kg (550 lbs)