51

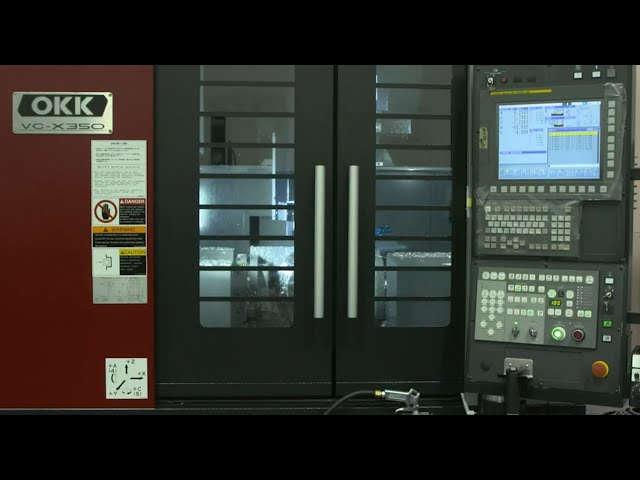

OKK

OKK VM76RII Vertical Machining Center

*Availability of machines is based on region. Contact your local Methods office to learn more.

The VM/R series increased rigidity of the main body and the spindle to provide even higher cutting performance. Its feed axes utilize highly rigid and accurate box-ways like conventional machines. This enables machining of not only general parts but also parts made of difficult-to-cut materials such as titanium. The main body design delivers heavy and accurate machining in an ergonomic friendly design.

Product Details

Features & Benefits

- Expanded working area

- Improved accessibility

- Increased main body rigidity

- Core chilled ball screws

- Double anchored support system

- Space saving design for economical use of floor space

- Coil-type chip conveyor

- box ways construction

Technical Data

Travel

- X-Axis Travel

- 60.6" (1540mm)

- Y-Axis Travel

- 29.9" (760mm)

- Z-Axis Travel

- 26.0" (660mm)

- Table Top to Spindle Nose

- 5.9" - 31.9" (150mm - 810mm)

Table

- Table Work Surface Area

- 61.0" x 29.9" ( 1550mm x 760mm)

- Table Load Capacity

- 3307 lbs (1500 kg)

Feed Rate

- Rapid Traverse Rate X/Y

- 945 in/min (24 m/min)

- Rapid Traverse Rate Z

- 787 in/min (20 m/min)

- Cutting Feed (X/Y/Z)

- 787 in/min (20 m/min)

Spindle

- Spindle Power

- 25/20 HP (Option 40HP)

- Spindle Speed

- 8,000 rpm (Option 12,000 rpm)

- Spindle Taper

- CAT50 (Option CAT40)

Tools

- Standard Number of Tools

- 30 (Option 40)

- Maximum Tool Weight

- 44 lbs (20 kg)

- Maximum Tool Length

- 15.0" (380 mm)

- Maximum Tool Diameter

- ø 4.06" (103 mm) / ø 7.87" (200 mm) without tool in adjacent pots

- Tool Changing Time- Tool to Tool

- 2.0 sec (Speed is changeable for heavy-weight tools)

General

- Machine Weight

- 28,700 lbs (13,000 kg)

- Machine Control

- FANUC F31i-B Plus