51

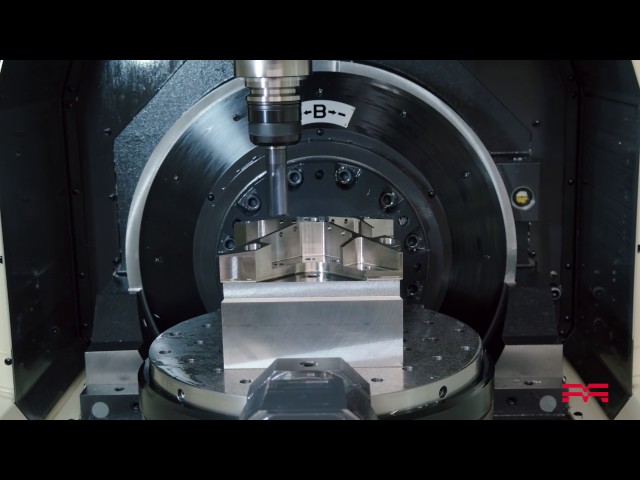

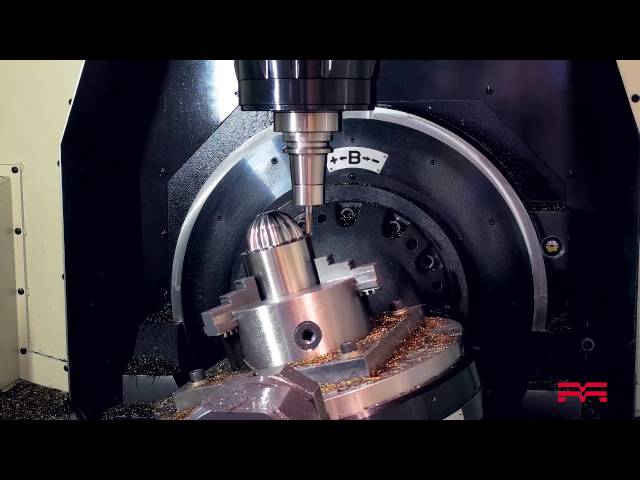

Yasda

YBM Vi40

The YBM Vi40 is a highly accurate, rigid, and reliable solution for 5-axis die and mold making. This machine can deliver high performance for high-precision machining of extremely hard materials in complicated shapes which are difficult for a 3-axis machine.

Product Details

Features & Benefits

- B/C Axis Tilt Rotary Table

- Direct Drive Spindle W/ Self-Adjusting Preload System

- Through Hardened (HR60) Box Guide Ways

- Optical Scale Feedback

- Symmetrical Bridge Structure

- Advanced Thermal Displacement

- 5 Sided Machining with a Single Set-up

- Rigid Structure Designed for Hard Milling Die Mold Applications

- Dramatically Reduces the Number of Process Steps and Time

- Machine Structure is Designed for High-precision and High Surface Part Quality

- Probing Systems

Technical Data

Travel

- X-Axis Travel

- 35.4 (900) in (mm)

- Y-Axis Travel

- 19.7 (500) in (mm)

- Z-Axis Travel

- 17.7 (450) in (mm)

- Distance from Table Surface to Spindle

- 3.9-21.7 (100-550) in (mm)

- B-Axis (tilt table)

- +110 to -110 degrees

- C-Axis (rotary table)

- 360º (0.0001º)

Feed Rate

- X, Y, and Z Axes Rapid Traverse

- 788 (20) in/min (m/min)

- B-Axis (titl) Rapid Traverse

- 20 rpm with Worm Gear

- C-Axis (rotary) Rapid Traverse

- 100 rpm with DD motor

- X, Y, and Z Axes Cutting Feed Rate

- 12,000 mm/min (472ipm) with HAS

- B-Axis (tilt) Cutting Feed Rate

- 20 rpm with HAS

- C-Axis (rotary) Cutting Feedrate

- 100 rpm with HAS

Table

- Table Working Surface

- 15.8x15.8 (400x400) in (mm)

- Table Loading Capacity

- 440 (200) lbs (kg)

Spindle

- Spindle Speed Range

- 100-24000 rpm (opt)

- Spindle Taper

- 7/24 taper No. 40 (Big Plus)

Tooling

- Number of Tools

- 60/100 std (opt)

- Maximum Tool Weight

- 14.4 (7) lbs (kg)

- Maximum Tool Length

- 9.8 (250) in (mm)

- Maximum Tool Diameter

- ø 2.8 (70) in (mm)

General

- Machine Weight

- 33070 (15000) lbs (kg)

- Machine Control

- FANUC 31i-B5 - 15" Color LCD