51

Yasda

PX30i

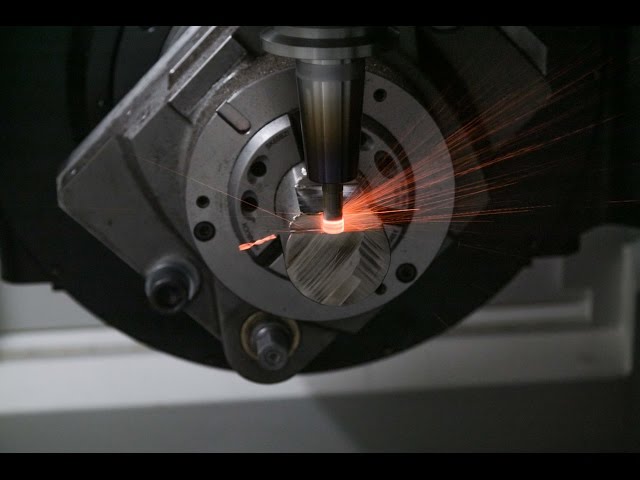

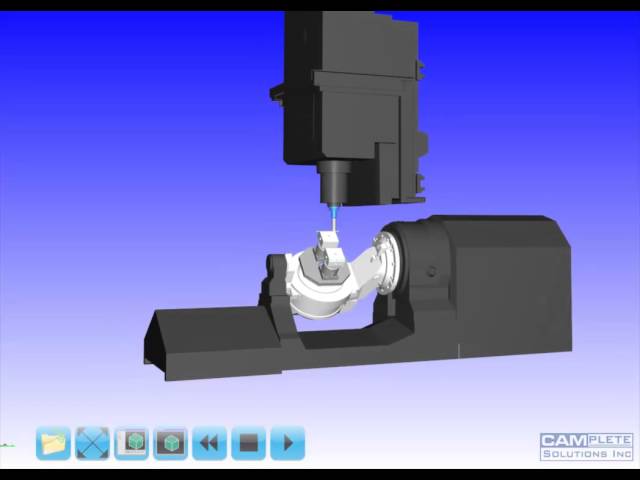

YASDA developed the 5-axis PX30i machine to supply customers with a top quality, highly reliable machine tool for the machine shop market and OEM users. The PX30i is outstanding in versatile 5-axis machining applications, precision parts, drilling, face milling, boring, and milling. The PX30i also excels in hardened steel and other tough materials like titanium and inconel. The PX30i has an excellent design for automation, usability and productivity.

Request Information

Or call 1-877-668-4262

Product Details

Features & Benefits

- 5 Axis High Precision Vertical Machining Center

- Large Work Envelope

- High Torque Spindle

- High Speed Direct Drive Rotary Axes

- Self-contained Multi Pallet Stacking System

- Space Saving Footprint

- System 3R Coupling for Pallet Clamping

- Rigid Machine Structure for Machining Various Material Types

- Optical Scale Feedback for Precise Positioning

- Probing Systems

Technical Data

Travel

- X-Axis Travel

- 26.8 (680) in (mm)

- Y-Axis Travel

- 15.8 (400) in (mm)

- Z-Axis Travel

- 19.7 (500) in (mm)

- Distance from Table Surface to Spindle

- 4.7-24.4 (120-620) in (mm)

- B-Axis (tilt table)

- +65 to -125 degrees

- C-Axis (rotary table)

- 360º (0.0001º)

Feed Rate

- X, Y, and Z Axes Rapid Traverse

- 2362 (60) in/min (m/min)

- B-Axis (tilt) Rapid Traverse

- 75 rpm with DD motors

- C-Axis (rotary) Rapid Traverse

- 125 rpm with DD motors

- Feed Rate

- 788 (20000) in/min (mm/min)

Table

- Table Working Surface

- 7.3x7.3 (185x185) in (mm)

- Table Loading Capacity

- 177 (80) lbs (kg)

- Max Diameter of Workpiece

- ø 15.8 (400) in (mm)

- Min. Table Indexing Angle

- -125 + 65 degree

Spindle

- Spindle Type

- Self adjusting pre-load

- Spindle Speed Range

- 100-20000 rpm

- Spindle Taper

- 7/24 taper No. 40 (Big Plus)

Tooling

- Number of Tools

- 323 std (513 opt)

- Maximum Tool Weight

- 22 (10) lbs (kg)

- Maximum Tool Length

- 12 (300) in (mm)

- Maximum Tool Diameter

- ø 3.2 (80) in (mm)

General

- Machine Weight

- 41227 (18700) lbs (kg)

- Machine Control

- FANUC 31i-B5-15" Color LCD