OKK

VM53R

*Availability of machines is based on region. Contact your local Methods office to learn more.

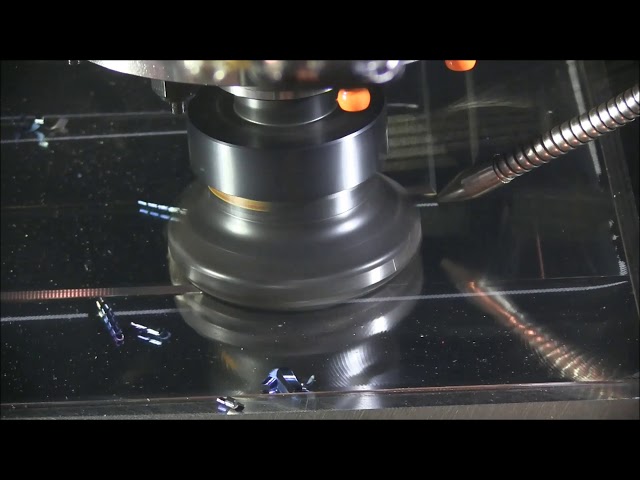

The VM/R series of OKK machines offers increased rigidity of the main body and the spindle to provide even higher cutting performance.

The OKK VM53R’s feed axes utilize highly rigid and accurate box-ways like conventional machines, enabling better machining of not only general parts, but also machining parts made of difficult-to-cut materials such as titanium. The main body design delivers heavy and accurate CNC machining in an ergonomic and user-friendly design.

Or call 1-877-668-4262

Product Details

Features & Benefits

- Expanded working area

- Improved accessibility

- Increased main body rigidity

- Box way construction

- Space saving design for economical use of floor space

- Coil-type chip conveyor

Technical Data

Travel

- X-Axis Travel

- 41.3" (1050mm)

- Y-Axis Travel

- 20.8" (530mm)

- Z-Axis Travel

- 20.1" (510mm)

- Table Top to Spindle Nose

- 5.9" - 26.0" (150mm - 660mm)

Table

- Table Work Surface Area

- 41.3" x 22.1" ( 1050mm x 560mm)

- Table Load Capacity

- 1764 lbs (800 kg)

Feed Rate

- Rapid Traverse Rate X/Y

- 1181 in/min (30 m/min)

- Rapid Traverse Rate Z

- 787 in/min (20 m/min)

- Cutting Feed (X/Y/Z)

- 787 in/min (20 m/min)

Spindle

- Spindle Power

- 25/20 HP

- Spindle Speed

- 8,000 rpm

- Spindle Taper

- CAT40 or CAT50

Tools

- Standard Number of Tools

- 30

- Maximum Tool Weight

- 44 lbs (20 kg)

- Maximum Tool Length

- 13.8" (350 mm)

- Maximum Tool Diameter

- ø 4.06" (103 mm) / ø 7.87" (200 mm) without tool in adjacent pots

- Tool Changing Time- Tool to Tool

- 2.0 sec (Speed is changeable for heavy-weight tools)

General

- Machine Weight

- 17,600 lbs (8,000 kg)

- Machine Control

- FANUC F31i-B