51

Methods

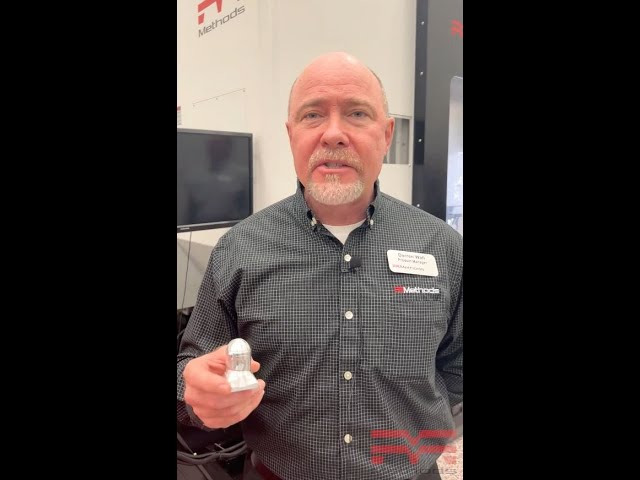

MB 650U

Introducing the all-new Methods MB 650U Simultaneous 5-Axis Bridge Type Machining Center, engineered & built to strict Methods specifications and quality standards.

This new product line from Methods is packed with standard features and benefits that will exceed the expectations of our customers looking for quality, reliability, accuracy and longevity at a competitive price.

Product Details

Features & Benefits

- 15,000 RPM Big Plus, 40 Taper Spindle with Air-Oil Lubrication, Spindle Chiller

- Powerful 25 HP Direct Drive Hollow Shaft Spindle Motor with 1,000 psi CTS Prep

- Robust Bridge Type Construction with Thermal Compensation

- High Performance FANUC 31i-MB5 PLUS Control with 15” TFT Screen

- Includes Tool Center Point Control, Collision Detection, 2 GB Data Server, Manual Guide I, AICC II, 600 Block Look Ahead and Ethernet

- Large Capacity 60 Tool ATC

- Includes Scales in All Axes & Kinematic Calibration Hardware/Software

Technical Data

Travel

- X axis Travel

- 24.4" (620 mm)

- Y axis Travel

- 20.5" (520 mm)

- Z axis Travel

- 18.1" (460 mm)

- B axis - Tilting

- -50° ~ +110°

- C axis - Rotary

- 360°

Table

- Table Dimensions

- Ø25.59 in (Ø650 mm)

- Maximum Load

- 661 lbs (300 kg)

- Spindle Nose to Table Surface

- 5.9” ~ 24” (150 ~ 610 mm)

Spindle

- Spindle Speed

- 15,000 rpm

- Spindle Taper

- Big Plus/CAT40

- Spindle Power

- 25 hp

- Spindle Torque

- 106 ft/lb (143.7 Nm)

- Spindle Lube

- Oil / Air

Feedrate

- X-Axis Rapid Traverse

- 1417 in/min (36 m/min)

- Y-Axis Rapid Traverse

- 1417 in/min (36 m/min)

- Z-Axis Rapid Traverse

- 1417 in/min (36 m/min)

- B/C Axes Rotation Speed

- 25 rpm

ATC

- Maximum Number of Tools

- 60

- Tool-to-Tool Change Time

- 1.9 sec

- Max Diameter

- 3.0" (75 mm)

- Max Weight

- 15.4 lbs (7 kg)

Dimensions/ Weight/ Capacities

- Weight

- 19,400 lbs (8800 kg)

- Coolant Tank Capacity

- 68.7 gal (260 L)

- Control

- FANUC 31i-MB5 Plus