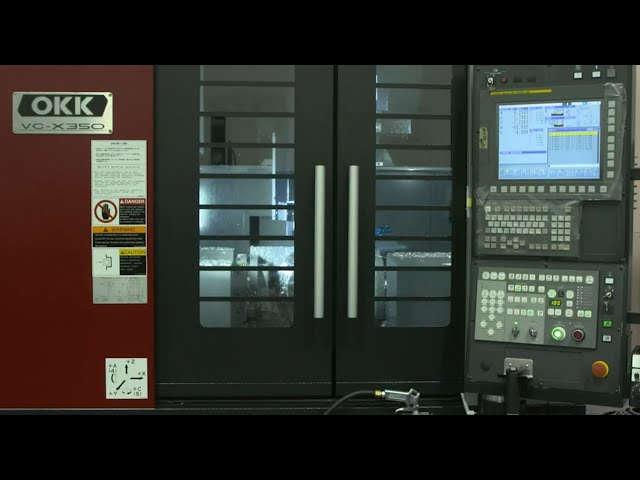

OKK

HM800S

*Availability of machines is based on region. Contact your local Methods office to learn more.

OKK‘s new concepts in high-speed machining offer drastic improvements in speed, rigidity and durability over competing machines. The HM series of OKK machines offers the fastest and most powerful machines in their class, while providing easy access, maintenance and operation.

Heavy duty cutting performance is delivered by incorporating a rigid frame of thick box-shaped structure to foundation the large linear roller guides designed for very heavy loads. High-speed rotation APC and ATC by synchronization cam (OKK patented) delivers smooth performance and production efficiency.

Product Details

Features & Benefits

- Direct-turn APC

- Heavy load capacity linear roller guides

- Core chilled pre-tensioned and double-anchored ball screws

- High load capacity feed motors

- Space saving design for economical use of floor space

Technical Data

Travel

- X-Axis Travel

- 41.3" (1050mm)

- Y-Axis Travel

- 35.3" (900mm)

- Z-Axis Travel

- 34.6" (880mm)

Table

- Table Top to Spindle Nose

- 2.4" – 37.8" (60mm - 960mm)

- Table Size

- 31.5" x 31.5" (800mm x 800mm)

- Table Load Capacity

- 2645 lbs (1200 kg)

- Max. Workpiece Size

- ø 43.7" (1110mm)

- Table Change Time: Cut to Cut

- 15.0 sec

Feed Rate

- Rapid Traverse Rate (X/Y/Z)

- 2953 in/min (75 m/min)

- Cutting Feed (X/Y/Z)

- 1574 in/min (40 m/min)

Spindle

- Spindle Power

- 60/35 HP

- Spindle Speed

- 12,000 rpm (OP: 8,000 rpm Three Geared Head 923ft-lbs)

- Spindle Taper

- CAT50

Tools

- Standard Number of Tools

- 60 (OP: 116/176/236)

- Maximum Tool Weight

- 55 lbs (25 kg)

- Maximum Tool Length

- 19.7" (500 mm)

- Maximum Tool Diameter

- ø 4.5" (115 mm) / ø 10.6" (270 mm) without tool in adjacent pots

- Tool Changing Time: Cut to Cut

- 4.2 sec (Speed is changeable for heavy-weight tools)

General

- Machine Weight

- 40,800 lbs (18,500 kg)

- Machine Control

- FANUC F31i-B5