Yasda

H-40i

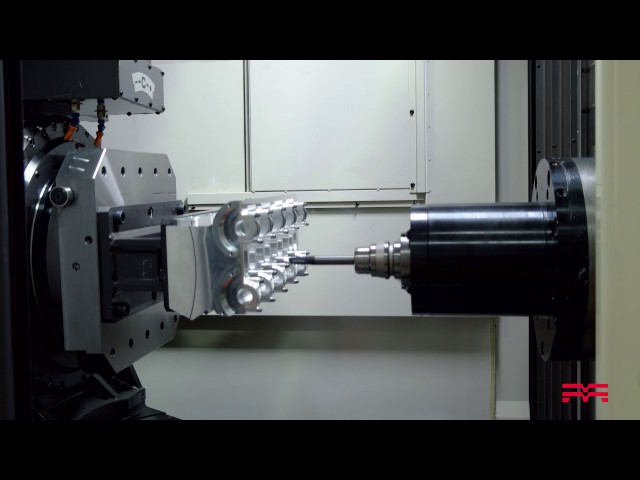

YASDA’s H40i 5-Axis Machining Center delivers improved and versatile machining performance with its 5-faces indexing application and complex simultaneous 5-axis machining applications, due to its high rigidity and high accuracy.

This Yasda machine‘s outstanding performance results not only in less setting up, but also increases your shop’s total profitability thanks to its many benefits that reduce machining costs.

H40i has options of 12PLS up to maximum 24PLS. Its reliable multiple pallets management options support versatile applications and long hours of automated production.

Product Details

Features & Benefits

- 5-Axis High Precision Horizontal Machining Center

- High Speed Direct Drive Rotary Axes

- Self-contained Multi Pallet Stacking System

- 20000 rpm Spindle Speed

- Space-Saving Footprint

- Rigid Machine Structure for Machining Various Material Types

- Scale Feedback for Precise Positioning

- Probing Systems

Technical Data

Travel

- X-Axis Travel

- 34.5 (875) in (mm)

- Y-Axis Travel

- 29.2 (740) in (mm)

- Z-Axis Travel

- 27 (685) in (mm)

- B-Axis (tilt table)

- +45 to -185 degrees

- C-Axis (rotary table)

- 360º (0.0001º)

- Distance from Table Surface to Spindle

- 29.2 (740) in (mm)

- Distance from Table Center to Spindle Nose Face

- 27 (685) in (mm)

Feedrate

- X, Y, and Z Axes Rapid Traverse

- 50,000 mm/min ( 1,968 ipm)

- B-Axis (tilt) Rapid Traverse

- 75 rpm with DD motors

- C Axis (rotary) Rapid Traverse

- 100 rpm with DD motors

- X, Y, and Z Axes Feed Rate

- Max. 20,000 mm/min ( 787 ipm) with HAS

- B and C Axes Feedrate

- Max. B: 40 / C: 40 rpm with HAS

Table

- Table Working Surface

- 15.8x15.8 (400x400) in (mm)

- Table Loading Capacity

- 440 (200) lbs (kg)

- Max Diameter of Workpiece

- ø 19.7 (500) in (mm)

- Min. Table Indexing Angle

- -185 to 45 degree

Spindle

- Spindle Type

- Direct Drive

- Spindle Speed Range

- 200-20000 rpm (opt)

- Spindle Taper

- 7/24 taper No. 40 (Big Plus)

Tooling

- Number of Tools

- 240 std (opt)

- Maximum Tool Weight

- 15.43 (7) lbs (kg)

- Maximum Tool Length

- 12 (300) in (mm)

- Maximum Tool Diameter

- ø 2.75 (70) in (mm)

General

- Machine Weight

- 24250 (11000) lbs (kg)

- Machine Control

- FANUC 31i-B5- 15" Color LCD